Wood Plastic Composite is a kind of wood made from plastic waste, the trend of circularity that currently prevails has led different actors to innovate in uses and materials of a large number of products, mainly to improve the environment.

How is this made?

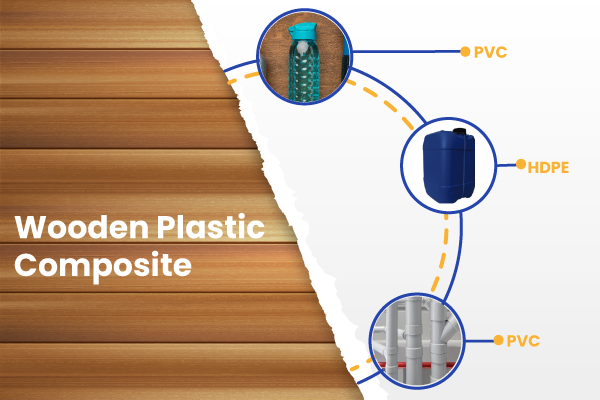

It is made with 60% of wood residues such as pieces, shavings, and sawdust, which if not used are discarded, in its manufacture lignocellulosic residues such as corn, cane, barley, etc. can also be used. For the remaining percentage, containers or containers made of High-Density Polyethylene, Polypropylene, PVC, or other thermoset polymers are used; The best thing is that even those bottles that had an industrial use with chemicals or agrochemicals, which pose a danger for the manufacture of another type of article, for the elaboration of Wood Plastic Composite is not the case.

Entrepreneurs who have decided to start with the manufacture of this innovative material must first approach collecting the raw material, in the case of the containers or containers they are washed, cut, and melted, to this mixture lignocellulosic residues are added to obtain the paste Once the desired shape is obtained, the Wood Plastic Composite goes through a cooling process to harden.

What is Wood Plastic Composite used for?

Its main use is in the construction industry for the manufacture of floors, walls, closets, posts, country houses, fences, planters, furniture, games, and much more. Wood Plastic Composite has advantages over conventional wood, firstly, it has a greater resistance to humidity, in the same way, to pests. In addition, its price is very competitive, so it is currently an ideal option for those applications that seek a sustainable turn in their processes.